Hello Industrial Partners!

In today’s fast-paced fabrication and industrial automation landscape, the demand for smarter, more compact, and higher-performance weld monitoring solutions has never been greater. Welders, engineers, and integrators alike are facing tighter spaces, higher quality standards, and increasing pressure to automate inspections.

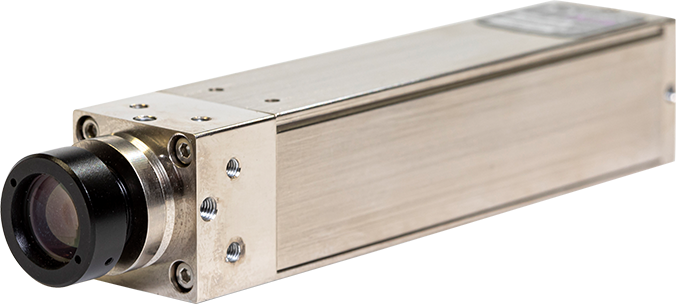

To meet these challenges head-on, Engrity WeldHub is proud to announce the availability of the Xiris XVC-700 Series, including the XVC-700 (Monochrome), XVC-710 (Color), and the XVC-750 (Near-Infrared) camera models. Built with next-generation technology and a miniature all-digital form factor, these weld cameras deliver the clarity, versatility, and durability required for today’s advanced welding applications.

A New Era of Compact Weld Cameras

One of the most impressive features of the XVC-700 Series is its ultra-slim 22 × 22 mm profile and incredibly lightweight 89 g body. This tiny footprint opens doors to weld imaging in places where traditional weld cameras simply cannot fit.

Whether you’re working with:

-

Pipe overlay and internal inspection setups

-

Orbital welding systems

-

Narrow-gap or hard-to-reach joints

-

Compact robotic welding cells

…the XVC-700 family brings weld imaging to environments previously considered inaccessible.

High Dynamic Range (HDR) Clarity You Can Trust

Capturing a weld arc and melt pool with accuracy is notoriously difficult due to intense brightness, reflections, and low-contrast surroundings. The XVC-700 Series overcomes these challenges with its 140 dB+ High Dynamic Range sensor, delivering:

-

Crystal-clear arc visibility

-

Sharp melt pool monitoring

-

Better contrast in extreme lighting

-

Accurate imaging for both pre-weld and post-weld conditions

With 1280 × 1024 resolution and frame rates up to 54 fps, each camera produces exceptionally detailed video, helping operators and AI systems make better decisions in real time.

Three Models — Unlimited Possibilities

Each camera in the XVC-700 family is designed with a specific imaging purpose in mind:

1. XVC-700 (Monochrome)

Perfect for high-contrast weld monitoring and general automation applications.

2. XVC-710 (Color)

Ideal for environments where color differentiation is essential to assess weld conditions, materials, or surroundings.

3. XVC-750 (Near-Infrared)

A standout model made for open-arc monitoring, especially during GMAW and GTAW operations.

The NIR sensitivity delivers improved visibility in high-brightness arcs and enables advanced AI-powered melt pool analysis.

Designed for Integration — Ready for Any Setup

Every model in the XVC-700 family is engineered with integration and installation simplicity at its core.

Key integration advantages include:

-

GigE + PoE connectivity via a single M12 X-coded cable

-

Up to 100 m cable length, ideal for large shop floors

-

6 W maximum power consumption

-

Interchangeable S-mount and select C-mount lenses

-

Optional high-temperature protection housings up to 260°C

-

Multiple angled optics options from 0° to 90°

Whether you’re integrating these cameras into a robot, automated welding system, or pipe welding station, setup is fast, clean, and reliable.

Why the XVC-700 Series Is a Game Changer for Industrial Weld Monitoring

The combination of compact size, strong HDR performance, and robust industrial connectivity makes the XVC-700 series one of the most versatile weld camera lines on the market.

Here’s what makes it stand out:

✔ Designed for tight and challenging environments

Its slimline frame allows placement where conventional weld cameras fail. Perfect for small-diameter pipe welding (as small as 100 mm / 4” diameter).

✔ Built for automation

Compatible with welding robots, automated manipulator arms, inspection tools, and more.

✔ Enhanced monitoring for quality and safety

Operators get real-time, high-quality visuals without the need to be near the weld—improving safety and reducing fatigue.

✔ AI-ready

The XVC-750’s NIR capabilities are ideal for machine learning, automated defect detection, and melt pool analytics.

Applications Across Industries

The XVC-700 Series is already transforming workflows across:

-

Pipeline construction and maintenance

-

Pressure vessel and structural fabrication

-

Automotive and aerospace manufacturing

-

Shipbuilding and offshore operations

-

Robotic and CNC welding systems

Anywhere precision, visibility, and automation matter—these cameras deliver.

Available Now on Engrity WeldHub

At Engrity WeldHub, we’re committed to providing inspectors, integrators, and fabrication teams with cutting-edge tools that elevate weld quality, improve workflow efficiency, and support digital transformation in the welding industry.

The XVC-700 Series brings the next level of weld intelligence—and now, it’s ready for deployment across your operations.

Final Thoughts

If your team needs improved weld visibility, better data, enhanced automation, or AI-driven monitoring, the XVC-700 Series is a powerful solution ready to meet those needs. Its combination of size, performance, and adaptability sets a new standard for industrial weld imaging.

To learn more, request a demo, or integrate these cameras into your welding setup, visit Engrity WeldHub today.

Weld Hub : https://engrity.com/engrity-weldhub

📧 Email: sales@engrity.com

📞 Phone: (780) 800-6297

Experience the Difference

Contact

Phone

+1 (780) 800-6297

info@engrity.com

Address:

201-9403 63 Ave NW, Edmonton, AB T6E 0G2