Hello Industrial Partners!

In modern fabrication, manufacturing, and inspection environments, the demand for higher precision, better visibility, and consistent weld quality continues to grow. As welding applications become more complex—especially in confined or hard-to-reach areas—traditional monitoring tools struggle to keep up.

This is where Engrity WeldHub, a division of Engrity Group, is setting a new industry benchmark. With years of experience in welding inspection, QA/QC, industrial support, and NDT services across Canada, Engrity has now expanded its expertise into delivering high-performance welding technologies. WeldHub’s mission is simple:

to equip welders, fabricators, and inspectors with the most advanced tools available—backed by expert support, reliable sourcing, and industry-level knowledge.

Today, we are proud to introduce one of the most innovative products in welding visualization technology:

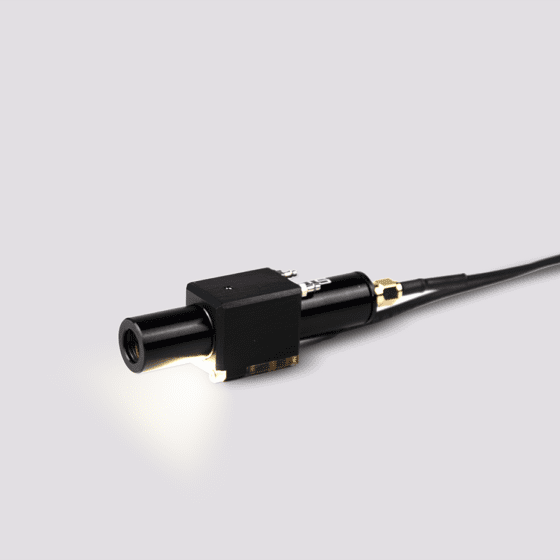

The Xiris XVC-310 Lipstick Weld Camera

A micro-sized, high-performance camera engineered for the tightest welding environments.

Why Weld Visibility Is Critical in Today’s Industrial Workflows

Whether welding pipelines, pressure vessels, tubing, or aerospace components, weld visibility is crucial. Operators need to understand:

-

How the melt pool moves

-

How the weld bead forms

-

Whether the seam is aligned

-

Whether the parent material is responding correctly

-

How wire feed is interacting with the molten pool

-

Whether heat input and arc stability are consistent

Any guesswork—or poor visibility—can lead to:

-

Inconsistent weld penetration

-

Excessive spatter or porosity

-

Misalignment

-

Rework or scrap

-

Costly delays

-

Safety risks

Traditional weld cameras often fail in:

-

Narrow gaps

-

Orbital welding setups

-

Deep grooves

-

Small-diameter piping

-

Enclosed chambers

Their size, heat sensitivity, or limited dynamic range make it difficult to capture usable, clear weld imagery.

The XVC-310 solves all of this.

Meet the Xiris XVC-310: The Industry’s Smallest High-Performance GTAW & Plasma Weld Camera

At only 17 mm in diameter and weighing just 80 grams, the Xiris XVC-310 is designed for the most challenging, space-restricted welding operations. Despite its size, it delivers imaging performance that rivals much larger systems.

Core Technical Specifications

-

Resolution: 1344 × 968 pixels

-

Dynamic Range: Over 120 dB HDR

-

Weight: 80 grams

-

Size: 17 mm Ø × 83 mm length

-

Compliance: CE, FCC, RoHS

What This Means for Operators

With its extremely high HDR capability, the XVC-310 can capture:

✔ Bright welding arcs

✔ Dark background material

✔ Melt pool detail

✔ Heat-affected zones

✔ Wire feed movement

—all at the same time, without glare, washout, or motion blur.

This gives welders and inspectors a real-time, crystal-clear view of the entire welding environment.

Perfect for Narrow Gap, Orbital, and Constrained Welding Applications

Some welding jobs simply cannot be monitored with standard tools. The XVC-310 is specifically designed for areas like:

-

Narrow groove welds

-

Orbital tube welding

-

Automated TIG processes

-

Plasma welding in enclosed chambers

-

Small-diameter pipe systems

-

Custom robotic welding cells

Its lipstick-shaped profile allows it to fit where virtually no other camera can.

Yet, unlike older lipstick cameras, the XVC-310 provides true HD color, high dynamic range, minimal distortion, and extreme durability.

Crystal-Clear Monitoring From Setup to Completion

One of the major advantages of the XVC-310 is its ability to provide visibility before, during, and after welding.

Operators can monitor:

-

TIG tip condition

-

Arc behavior

-

Melt pool movement

-

Weld bead formation

-

Joint alignment and seam tracking

-

Heat affected zones

-

Wire feed consistency

This ensures:

-

Fewer errors

-

Faster adjustments

-

Better weld repeatability

-

Higher overall quality

Whether used for manual assistance, operator training, or full automation, the camera enhances every part of the workflow.

Next-Level Software: Xiris WeldStudio™ 3

Camera hardware is only as powerful as the software that supports it.

The XVC-310 integrates seamlessly with Xiris WeldStudio™ 3, one of the most advanced welding visualization platforms available.

Key Software Features

-

Touchscreen control

-

Real-time image processing

-

Graphical overlay tools

-

Multi-camera control

-

Full video recording and playback

-

Snapshot and documentation features

-

Easy calibration tools

-

Optional WeldStudio™ 3 Pro for advanced analysis

This software significantly improves operator awareness and inspection documentation.

A Complete, Customizable System — Available Through Engrity WeldHub

When industries purchase the XVC-310 through Engrity WeldHub, they also gain access to a full suite of accessories and support components.

Available Accessories Includes:

-

Micro lenses designed for GTAW and Plasma

-

Industrial housings

-

Camera cables and extension cables

-

Controllers and interface modules

-

Power adapters

-

HMIs

-

Welding microphones

-

Cooling and protection solutions

-

Mounting brackets and holders

Engrity ensures that customers receive a fully integrated, plug-and-play solution, not just a camera.

Every setup is tailored to each client’s unique welding environment.

Where the XVC-310 Excels: Industry Applications

This camera becomes a valuable asset across multiple industries:

Oil & Gas

For pipeline tie-ins, pressure piping, and confined TIG operations.

Aerospace & Aviation

High-precision welding where accuracy is non-negotiable.

Power Generation

Nuclear and thermal plants requiring narrow gap welding.

Petrochemical & Refining

Reactor repairs, shutdown welding, and tight-access joints.

Automotive & Manufacturing

Robotic TIG welding cells and automated welding lines.

Fabrication Shops

For quality control, operator training, and documentation.

Wherever weld accuracy and visibility matter, the XVC-310 delivers immediate value.

**Why Engrity WeldHub?

Your Trusted Partner in Welding Technology**

WeldHub is not just an equipment supplier—we are a complete welding solutions provider.

We bring:

-

Years of industry experience in QA/QC, Inspection, and NDT

-

Deep understanding of welding processes and field challenges

-

Direct partnership with Xiris Automation

-

Access to premium welding technology and accessories

-

Fast support, expert guidance, and technical assistance

Engrity WeldHub was built to bridge the gap between advanced welding technology and real-world industrial needs.

Our customers benefit not just from the equipment, but from the knowledge and expertise behind it.

Small, Powerful, and Built for Precision — The Future of Weld Monitoring Has Arrived

With the Xiris XVC-310 now available through Engrity WeldHub, industries finally have access to a weld camera that is compact, durable, and exceptionally detailed—perfect for the high-precision demands of modern fabrication.

If your team is looking to enhance weld quality, improve safety, streamline inspections, or adopt better visibility tools for tight-access welding, the XVC-310 is the ideal upgrade.

Ready to Transform Your Welding Workflow?

Contact Engrity WeldHub today to learn more, request pricing, or book a consultation on how the XVC-310 can fit into your operation.

Your welds deserve absolute clarity—

and with the XVC-310, clarity is exactly what you get.

To learn more, request a demo, or integrate these cameras into your welding setup, visit Engrity WeldHub today.

Weld Hub : https://engrity.com/engrity-weldhub

📧 Email: sales@engrity.com

📞 Phone: (780) 800-6297

Experience the Difference

Contact

Phone

+1 (780) 800-6297

info@engrity.com

Address:

201-9403 63 Ave NW, Edmonton, AB T6E 0G2